|

6978| 2

|

[资讯] 3D打印仿生碳纤维橡胶车 |

|

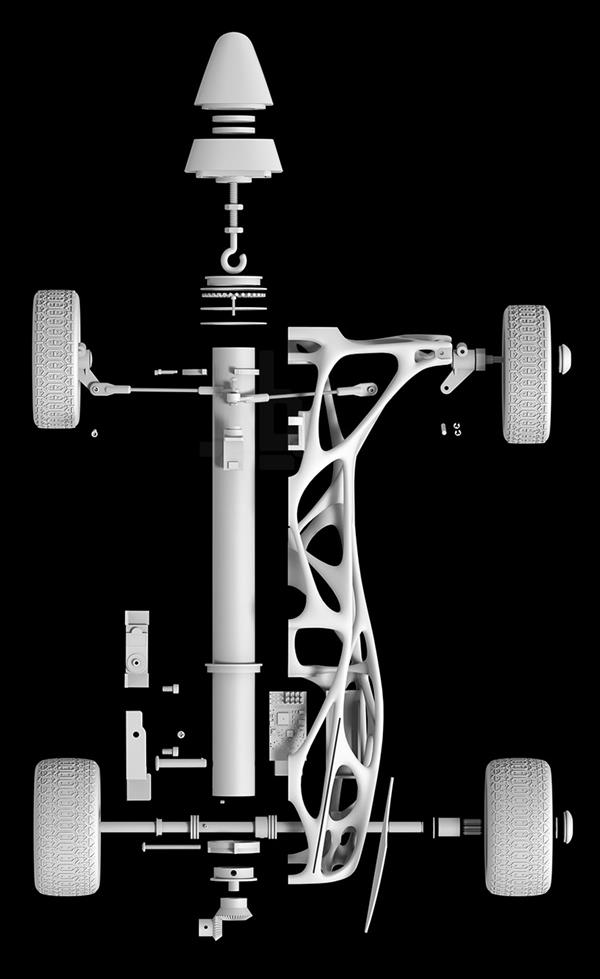

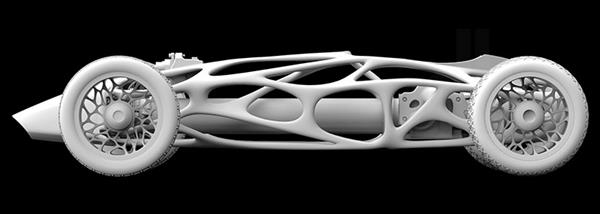

本帖最后由 swanglei 于 2015-1-28 12:03 编辑 转自3ders.org 原文链接:http://www.3ders.org/articles/20 ... d-cirin-rc-car.html Pasadena students 3D print a rubber band-powered Cirin RC car with a top speed of 30 mphI doubt many kids nowadays would be particularly thrilled when promised an elastic-powered car. While it was different in my time, the vast array of electric toys and high-quality video games available nowadays certainly increase expectations. However, I do not doubt that many kids would be absolutely thrilled by this impressive creation by three students from the Pasadena-based Art Center College of Design: a 3D printed RC car, powered by elasticity, that can reach a top speed of 30 miles per hour.    It’s called the Cirin and has been built by the three students Max Greenberg, Sameer Yeleswarapu, and Ian Cullimore. As they explained, their whole purpose was to create ‘a vehicle that would combine all of our past engineering education with the sculpture and industrial design skills we have acquired at art center. we drew inspiration from mid-1950’s formula 1 cars as well as the truss structures found inside the bones of a birds wing. these structure are both light and rigid, ideal properties for the car we wanted to design.’ While it certainly looks impressive and futuristic, its most interesting feature is an old-fashioned and remarkably simple technique: elasticity. Hidden away in its body is a 16-foot long elastic band, that needs to be firmly wound up with a power tool. The result? Enough power to propel the vehicle forward for several hundred feet, reaching a top speed of 30 mph. That’s impressive even for an electric car, never mind an elastic-powered one.    Moreover, the little vehicle can even be controlled, up to a certain extent. A handful of battery-powered electronics are included, providing steering and breaking possibilities. While these slightly detract from its identity as an elastic-powered RC car, it remains one of the most impressive 3D printed toys I’ve come across. But as you might have guessed, this unfortunately had little to do with a desktop FDM 3D printer. To Instead, they’ve 3D printed this gorgeous futuristic vehicle in nylon using selective laser sintering. Fortunately, they were sponsored by 3D printing service provider Solidconcepts, who did the actual printing. Before that, they went through various iterations in Solidworks, Rhino and T-splines to creative their biological-looking form without compromising on functionality. Its clever design and sturdy material will, they ensure us, easily resist the pressures that the elastic band unleashes upon it.   |

沪公网安备31011502402448

沪公网安备31011502402448© 2013-2026 Comsenz Inc. Powered by Discuz! X3.4 Licensed