本帖最后由 virtualwiz 于 2016-9-20 20:48 编辑

巡迹车估计是入门Arduino的同学们玩厌了的项目了吧

只要在地上贴个黑线,借助光学传感器和一些控制手段,就可以让小车(或者高大上一些的,Vortex)一路沿着黑线行驶。

简单点的做法,只要用红外反射传感器,电压比较器和几片逻辑器件就可以晃晃悠悠起来

复杂点的做法,可以用一大堆光学传感器,在高性能的单片机上运行PID算法,做出可以竞速的智能车

这回我们来做个不一样的巡迹车~~

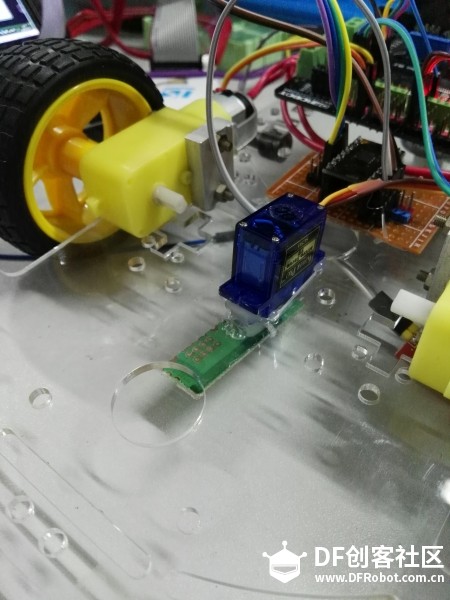

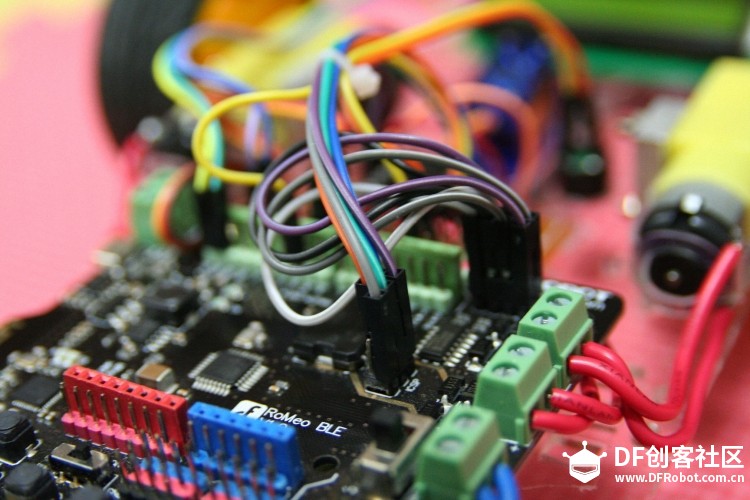

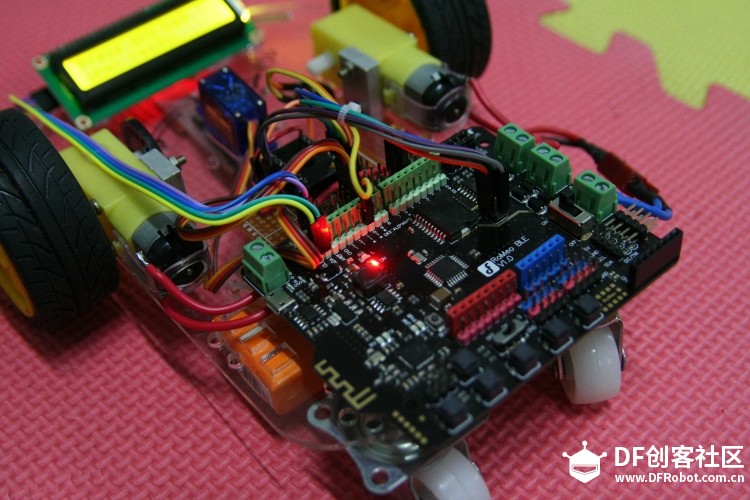

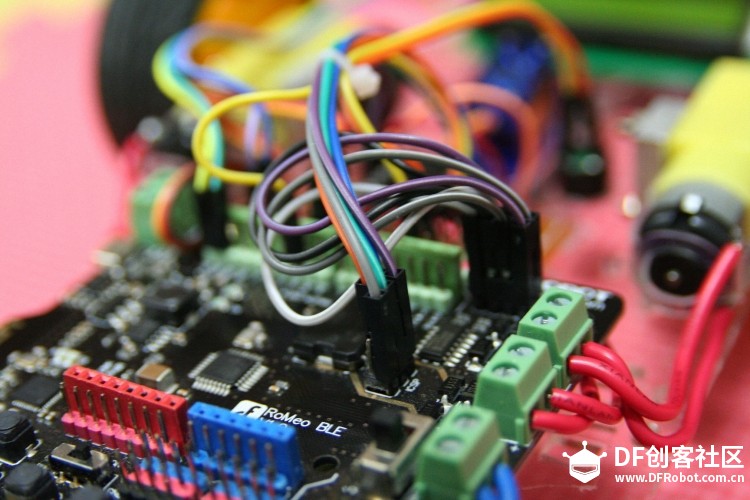

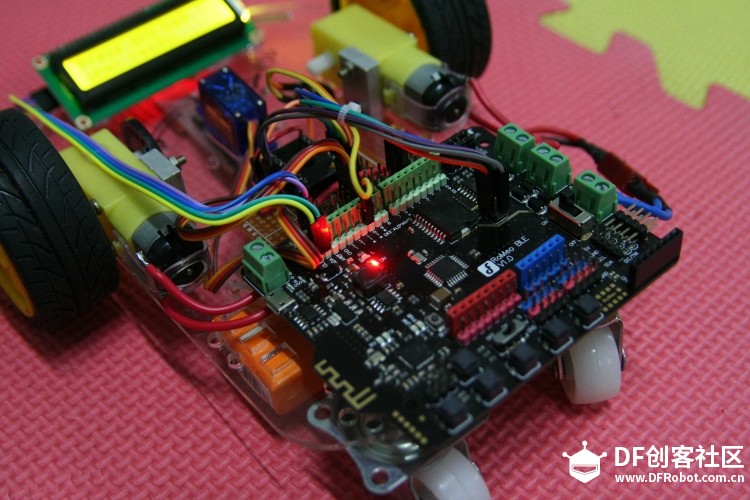

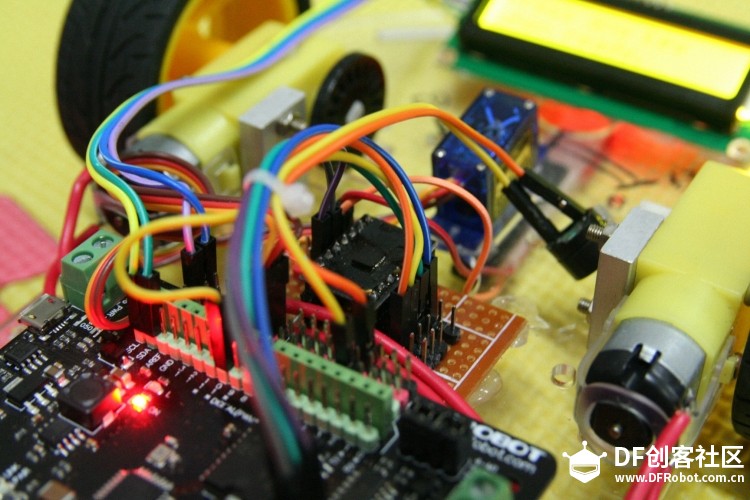

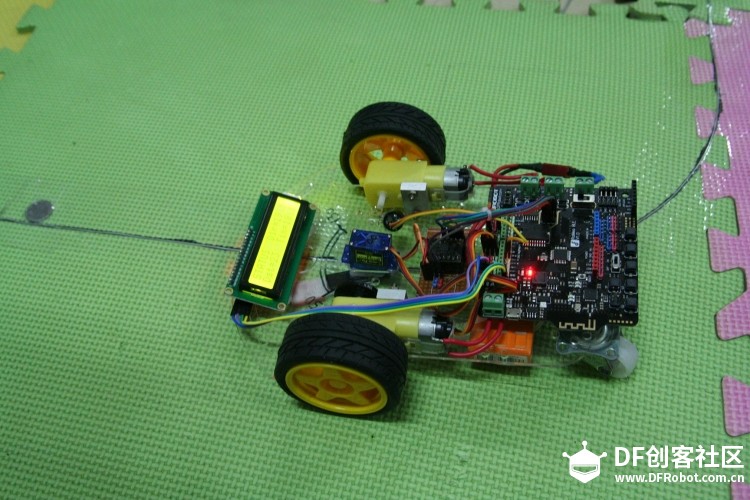

这个小车用到了DFRobot的Romeo BLE控制器,板载蓝牙和电机驱动,做这种项目灰常合适

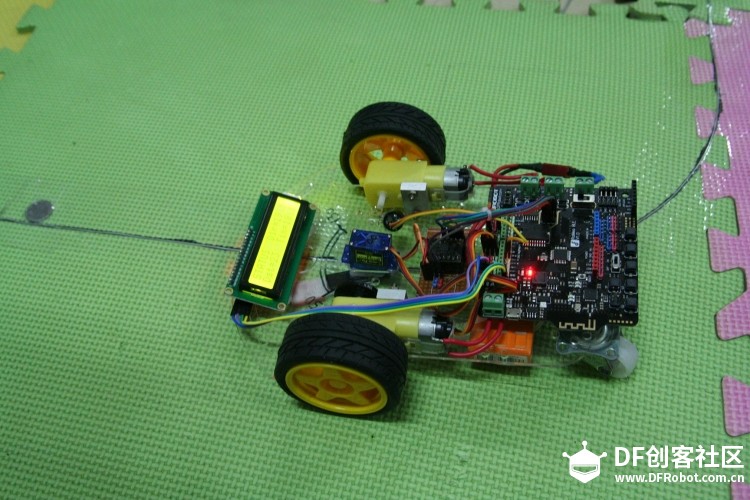

小车启动后,沿着一根直径1mm的细铁丝慢慢前进。轨道的随机位置会出现一枚硬币,小车巡迹途中如果遇到硬币,会发出报警声。

(参加过某比赛的同学们别笑我:lol)

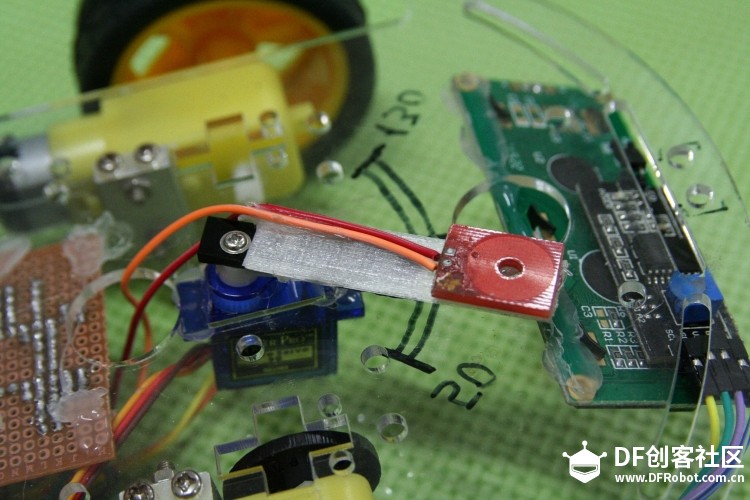

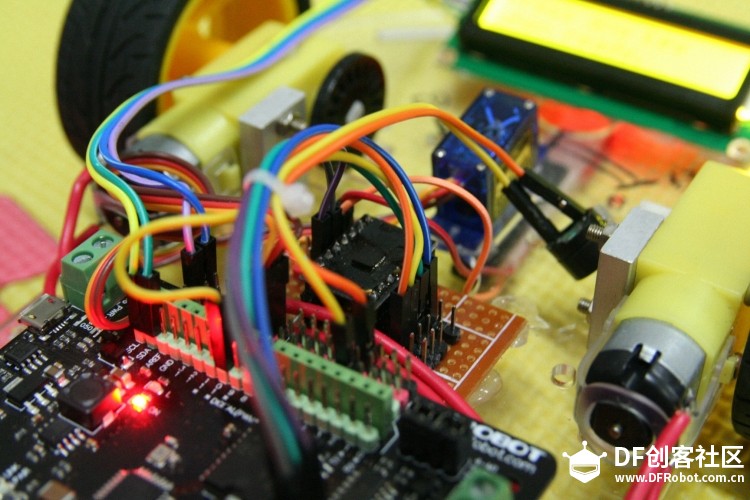

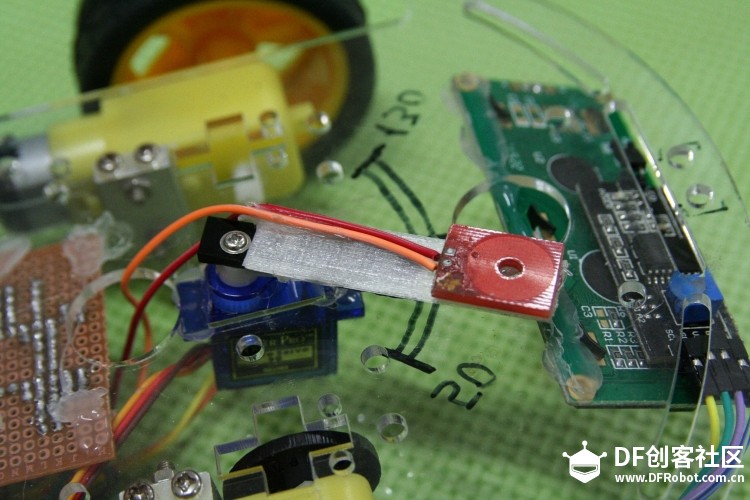

因为要检测的是细铁丝,可以使用TI公司的LDC1000数字电感传感器。

粗略地说,原理大概就是,

让一个空心的线圈靠近导体,这时导体就充当了线圈的铁芯,线圈的电感就会略微增加。LDC传感器以很高的频率扫描线圈,当电感特性发生了变化,就说明有导体靠近线圈,这就测出了我们需要的信息。

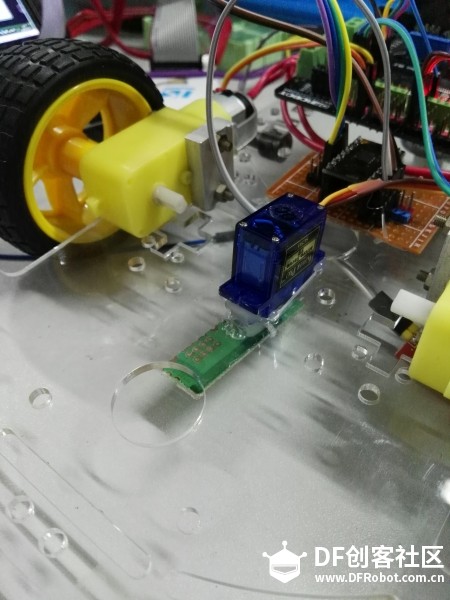

然后找个舵机,把线圈固定在一个杆上,让舵机来回扫动,同时不断读取LDC传感器的数据。这样,哪里测得的信号最强,就是细铁丝最有可能出现的方向,根据这个数值调整车的方向就可以了

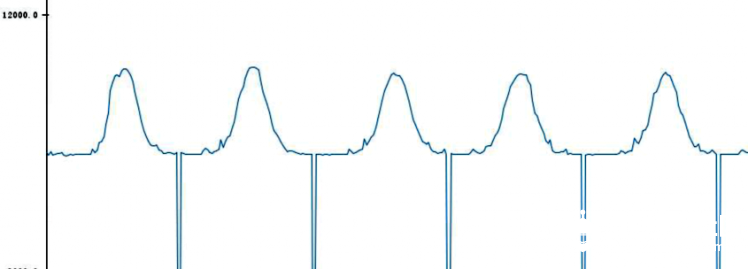

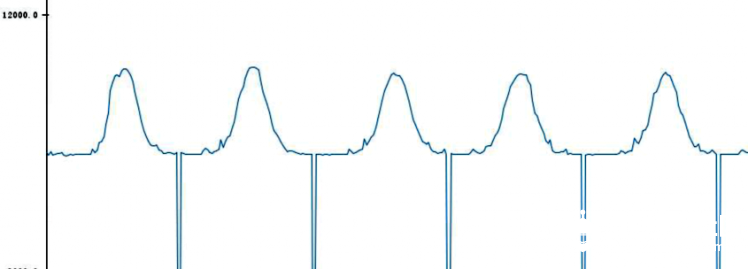

这是舵机扫描过程中用串口绘图器画出的波形,上方峰值的位置就是最可能出现铁丝的位置。

Romeo上的电机驱动跳线使用了一种不同寻常的接法,将右上方的跳线交叉相连,将PWM信号从L298N的DIR引脚送入,经过测试,这种接法可以显著提升直流电机的低转速性能,但是同时会增加驱动芯片和电机的发热量。

送上代码~~据说写代码要规范,别人看到才会舒服。

- <font face="Verdana">

-

- //3rd version

-

- #include <Servo.h>

- #include "SPI.h"

- #include <LiquidCrystal_I2C.h>

- #include <Wire.h>

-

- #define GPIO_MOT_LEFT_EN 5

- #define GPIO_MOT_RIGHT_EN 6

- #define GPIO_MOT_LEFT_DIR 4

- #define GPIO_MOT_RIGHT_DIR 7

- #define GPIO_SENSOR_SERVO 8

- #define GPIO_BUZZER 3

- #define GPIO_KEY A7

- #define GPIO_LED 13

-

- #define NAVI_DISTANCE_K 0.04

- #define NAVI_MOT_PULSEWIDTH 100

-

- #define IDLE_L 127

- #define IDLE_R 127

-

- #define SCAN_STARTPOS 50

- #define SCAN_ENDPOS 130

- #define SCAN_CENTER 90

-

- #define CONTROL_KP 3

- #define CONTROL_RUNSPEED 60

- #define CONTROL_TURNSPEED 50

-

- #define NAVI_TURNTHRE 6

-

- #define SIGNAL_COIN 20000

-

- #define SERVO_SLPTIME 3

-

- #define SCAN_SLPTIME 50

-

- const int CSB = 10;

-

- //Hardware driver

- Servo ScannerArm;

- LiquidCrystal_I2C lcd(0x27,16,2);

-

-

- void SetMotorDuty(byte L,byte R) {

- analogWrite(GPIO_MOT_LEFT_EN,L);

- analogWrite(GPIO_MOT_RIGHT_EN,R);

- }

-

- void Motor_Crank() {

- digitalWrite(GPIO_MOT_LEFT_DIR,HIGH);

- digitalWrite(GPIO_MOT_RIGHT_DIR,HIGH);

- }

-

- void Motor_Standby() {

- digitalWrite(GPIO_MOT_LEFT_DIR,LOW);

- digitalWrite(GPIO_MOT_RIGHT_DIR,LOW);

- }

-

- void GPIO_Init() {

- pinMode(GPIO_MOT_LEFT_EN,OUTPUT);

- pinMode(GPIO_MOT_RIGHT_EN,OUTPUT);

- pinMode(GPIO_MOT_LEFT_DIR,OUTPUT);

-

- pinMode(GPIO_MOT_RIGHT_DIR,OUTPUT);

-

- pinMode(GPIO_BUZZER,OUTPUT);

- pinMode(GPIO_LED,OUTPUT);

- SetMotorDuty(0,0);

- }

-

-

- void Serial_LDCSensor_Init() {

- unsigned int data = 0;

- Serial.begin(9600);

- // start SPI library/ activate BUS

- SPI.begin();

-

- pinMode(CSB, OUTPUT);

- SPI.setBitOrder(MSBFIRST);

- SPI.setDataMode(SPI_MODE0); // CPOL = 0 and CPH = 0 mode 3 also works

- SPI.setClockDivider(SPI_CLOCK_DIV4); // set SCLK @ 4MHz, LDC1000 max is 4MHz DIV2 also works

-

- // set power mode to idle to configure stuff

- digitalWrite(CSB, LOW);

- SPI.transfer(0x0B);

- SPI.transfer(0x00);

- digitalWrite(CSB, HIGH);

- delay(100);

-

- // Set RpMax

- digitalWrite(CSB, LOW);

- SPI.transfer(0x01);

- SPI.transfer(0x0E);

- digitalWrite(CSB, HIGH);

- delay(100);

- // Set RpMin

- digitalWrite(CSB, LOW);

- SPI.transfer(0x02);

- SPI.transfer(0x3B);

- digitalWrite(CSB, HIGH);

- delay(100);

-

- // Set Sensor frequency

- digitalWrite(CSB, LOW);

- SPI.transfer(0x03);

- SPI.transfer(0x94);

- digitalWrite(CSB, HIGH);

- delay(100);

-

- // Set LDC configurationn

- digitalWrite(CSB, LOW);

- SPI.transfer(0x04);

- SPI.transfer(0x17);

- digitalWrite(CSB, HIGH);

- delay(100);

-

- // Set clock configuration

- digitalWrite(CSB, LOW);

- SPI.transfer(0x05);

- SPI.transfer(0x00);

- digitalWrite(CSB, HIGH);

- delay(100);

-

-

- // disable all interrupt modes

- digitalWrite(CSB, LOW);

- SPI.transfer(0x0A);

- SPI.transfer(0x00);

- digitalWrite(CSB, HIGH);

- // set thresh HiLSB value

- digitalWrite(CSB, LOW);

- SPI.transfer(0x06);

- SPI.transfer(0x50);

- digitalWrite(CSB, HIGH);

- delay(100);

- // set thresh HiMSB value

- digitalWrite(CSB, LOW);

- SPI.transfer(0x07);

- SPI.transfer(0x14);

- digitalWrite(CSB, HIGH);

- delay(100);

- // set thresh LoLSB value

- digitalWrite(CSB, LOW);

- SPI.transfer(0x08);

- SPI.transfer(0xC0);

- digitalWrite(CSB, HIGH);

- delay(100);

- // set thresh LoMSB value

- digitalWrite(CSB, LOW);

- SPI.transfer(0x09);

- SPI.transfer(0x12);

- digitalWrite(CSB, HIGH);

- delay(100);

-

- // set power mode to active mode

- digitalWrite(CSB, LOW);

- SPI.transfer(0x0B);

- SPI.transfer(0x01);

- digitalWrite(CSB, HIGH);

- delay(100);

-

- }

-

- void Alarm(byte type) {

- switch(type)

- {

- case 1:

- tone(GPIO_BUZZER,1109,220);

- delay(220);

- tone(GPIO_BUZZER,1245,220);

- delay(220);

- tone(GPIO_BUZZER,1397,220);

- delay(220);

- noTone(GPIO_BUZZER);

- break;

-

- case 2:

- tone(GPIO_BUZZER,1397,220);

- delay(220);

- tone(GPIO_BUZZER,1109,220);

- delay(220);

- tone(GPIO_BUZZER,1661,220);

- delay(220);

- noTone(GPIO_BUZZER);

- break;

-

- case 3:

- tone(GPIO_BUZZER,1109,50);

- delay(50);

- noTone(GPIO_BUZZER);

- break;

-

- case 4:

- tone(GPIO_BUZZER,1397,150);

- delay(150);

- tone(GPIO_BUZZER,1661,150);

- delay(150);

- tone(GPIO_BUZZER,2794,150);

- delay(150);

- tone(GPIO_BUZZER,2217,150);

- delay(150);

- tone(GPIO_BUZZER,2489,150);

- delay(150);

- tone(GPIO_BUZZER,3322,150);

- delay(150);

- }

- }

-

- void Servo_Init() {

- ScannerArm.attach(GPIO_SENSOR_SERVO);

- ScannerArm.write(90);

- }

-

- void Display_Init(){

- lcd.init();

- lcd.backlight();

- //lcd.blink();

- }

-

- bool CoinFoundFlag = false;

-

- int LDC_SingleScan() {

- unsigned int val = 0;

- unsigned int dataLSB = 0;

- unsigned int dataMSB = 0;

- unsigned int proximitydata = 0;

-

- // Read proximity data LSB register

- digitalWrite(CSB, LOW);

- SPI.transfer(0xA1); // 0x80 + 0x21

- dataLSB = SPI.transfer(0x00);

- digitalWrite(CSB, HIGH);

- delay(SERVO_SLPTIME);

-

- // Read proximity data MSB register

- digitalWrite(CSB, LOW);

- SPI.transfer(0xA2); // 0x80 + 0x22

- dataMSB = SPI.transfer(0x00);

- digitalWrite(CSB, HIGH);

- delay(SERVO_SLPTIME);

-

- proximitydata = ((unsigned int)dataMSB << 8) | (dataLSB);// combine two registers to form 16bit resolution proximity data

- if(proximitydata == 0) Alarm(3);

- Serial.println(proximitydata);

- // Serial.print("\t");

- return proximitydata;

- }

-

- byte LDC_AutoScan() {

- static signed char ScanDirection = 1;

- int MaxSignalOnPos = 0;

- int MaxSignal = 0;

- int LDCReadBuf = 0;

- int Start;

- int End;

- if(ScanDirection == 1)

- {

- Start = SCAN_STARTPOS;

- End = SCAN_ENDPOS;

- }

- else

- {

- End = SCAN_STARTPOS;

- Start = SCAN_ENDPOS;

- }

- for(int CurrentPos = Start ; CurrentPos != End ; CurrentPos += ScanDirection)

- {

- LDCReadBuf = LDC_SingleScan();

- ScannerArm.write(CurrentPos);

- if(LDCReadBuf > MaxSignal)

- {

- MaxSignal = LDCReadBuf;

- MaxSignalOnPos = CurrentPos;

- }

- }

- ScanDirection = -ScanDirection;

- if(MaxSignal >= SIGNAL_COIN) {

- Alarm(4);

- CoinFoundFlag = true;

- }

- return MaxSignalOnPos;

- }

-

- int LDCValueMax = 1;

- int LDCValueMin = 0;

-

- void LDC_StartCalibration()

- {

-

- }

-

- void LCD_Format() {

- lcd.setCursor(0,0);

- lcd.print("STATUS Dir= ");

- lcd.setCursor(0,1);

- lcd.print("Dst= Tim= ");

- }

-

- void LCD_ShowInfo(int dir,int dst,int time) {

- lcd.setCursor(12,0);

- lcd.print(dir);

- lcd.setCursor(4,1);

- lcd.print(dst);

- lcd.setCursor(12,1);

- lcd.print(time);

- }

-

- byte SpeedWidthLimit(int orig){

- byte dest = orig;

- if(orig >= 255) dest = 254;

- if(orig <= 0 ) dest = 1;

- return dest;

- }

-

- int Run_Time;

-

- void setup() {

- Serial_LDCSensor_Init();

- GPIO_Init();

- Servo_Init();

- Display_Init();

- lcd.setCursor(0,0);

- lcd.print("Press any key");

- lcd.setCursor(0,1);

- lcd.print(" [PLL MODE]");

- Alarm(1);

- while(analogRead(GPIO_KEY) > 900);

- Alarm(2);

- delay(1000);

- SetMotorDuty(IDLE_L,IDLE_R);

- delay(1000);

- Run_Time = millis() / 1000;

- // while(1) LDC_SingleScan();

- }

-

- int Distance = 0;

- void loop() {

- int Duty_Left;

- int Duty_Right;

- int PeakAngle = LDC_AutoScan() - 90;

- if(PeakAngle <= NAVI_TURNTHRE && PeakAngle >= -NAVI_TURNTHRE)

- {

- Duty_Left = IDLE_L + CONTROL_RUNSPEED + (CONTROL_KP * PeakAngle);

- Duty_Right = IDLE_R + CONTROL_RUNSPEED - (CONTROL_KP * PeakAngle);

- }

- else

- {

- Duty_Left = IDLE_L + CONTROL_TURNSPEED + (CONTROL_KP * PeakAngle);

- Duty_Right = IDLE_R + CONTROL_TURNSPEED - (CONTROL_KP * PeakAngle);

- }

- Motor_Crank();

- if(CoinFoundFlag)

- {

- SetMotorDuty(IDLE_L + CONTROL_RUNSPEED + 20,IDLE_R + CONTROL_RUNSPEED + 20);

- CoinFoundFlag = false;

- }

- else

- {

- SetMotorDuty(SpeedWidthLimit(Duty_Left),SpeedWidthLimit(Duty_Right));

- }

-

- Distance += NAVI_DISTANCE_K * CONTROL_RUNSPEED;

-

- delay(NAVI_MOT_PULSEWIDTH);

-

- SetMotorDuty(IDLE_L,IDLE_R);

- LCD_Format();

- LCD_ShowInfo(PeakAngle , Distance , millis() / 1000 - Run_Time);

- Motor_Standby();

- //Serial.println(LDC_AutoScan());

- }

-

-

- </font>

|

活跃会员

活跃会员

老版主限定

老版主限定

蘑菇人

蘑菇人

沪公网安备31011502402448

沪公网安备31011502402448